In the rapidly evolving world of automotive technology, ensuring the safety and reliability of electronic and software systems is crucial. ISO 26262, the international standard for functional safety in the automotive industry, provides comprehensive guidelines for reducing risks and enhancing safety. This article explores why semiconductor development companies should pay attention to this standard and the significant benefits of compliance.

What is ISO 26262?

ISO 26262 is an international standard that ensures the functional safety of electrical and electronic systems in vehicles. From electronic control units (ECUs) to sensors and semiconductors, it outlines requirements and processes to address and minimize potential risks in development. Adhering to this standard guarantees the safe and reliable operation of electronic components, preventing critical failures that could endanger lives.

Why Should Semiconductor Development Companies Focus on ISO 26262?

Shifting Paradigm in the Automotive Industry

With the rise of autonomous and electric vehicles, the reliance on electronic components in vehicles has increased dramatically. From advanced driver assistance systems (ADAS) to electronic components, semiconductor technology is at the core of these functions. As such, the safety and reliability of semiconductors have never been more critical.Direct Impact of Safety Issues

Malfunctions in semiconductors can cause ECUs to misinterpret sensor signals or distort control signals, potentially compromising safety-critical functions like braking, steering, and airbags. Techniques like FMEA (Failure Mode and Effects Analysis) and FMEDA (Failure Mode, Effects, and Diagnostics Analysis) in ISO 26262 are essential for identifying and mitigating these risks systematically.Meeting OEM and Tier 1 Requirements

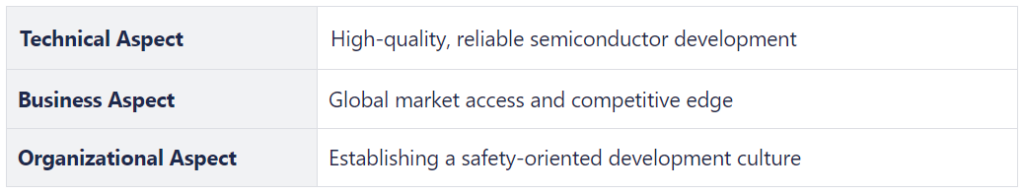

Original Equipment Manufacturers (OEMs) and Tier 1 suppliers demand that semiconductors meet ISO 26262 requirements. Non-compliance can result in restricted market access or increased validation costs. On the other hand, compliance facilitates smoother collaboration and expands business opportunities.Gaining Market Competitiveness

Achieving ISO 26262 certification is not just about ensuring safety; it is also a strong indicator of quality and reliability. Semiconductors labeled “ISO 26262 Compliant” have a competitive edge in collaborations with OEMs and Tier 1 suppliers prioritizing safety and quality.

Benefits of ISO 26262 Compliance

Risk Prevention and Efficient Management

ISO 26262 helps identify and address potential defects early in the semiconductor development process, significantly reducing the costs of recalls or defect management post-launch.Global Reliability

Compliance with international standards is a vital indicator in collaborations with global OEMs and suppliers, directly contributing to expanded business opportunities.Structured Development Processes

It fosters systematic processes for requirements management, configuration management, testing, and validation. These processes enhance organizational development capabilities and strengthen quality.Establishing a Safety Culture

ISO 26262 naturally cultivates a “safety-first” culture within organizations. Engineers prioritize safety requirements, positively influencing the company’s overall practices.

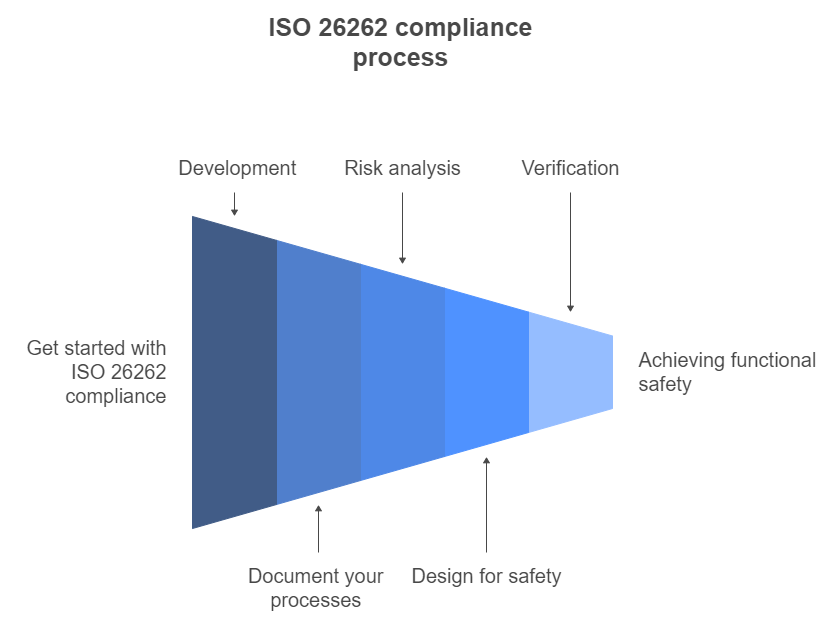

Steps to ISO 26262 Compliance

Organizational Strategy Development

Executive decisions and resource investments are essential for ISO 26262 certification. Securing skilled personnel or consulting support is advisable for initial process establishment.Process Establishment and Documentation

Document each step, such as requirements management, design, and validation, and continuously update them. Ensure functional safety activities are embedded across the semiconductor lifecycle.Risk Analysis and Safety Design

Apply analysis techniques like FMEDA to identify potential defects and implement countermeasures. Safety mechanisms, including error correction codes and fail-safe designs, should be integrated during the design phase.Verification and Feedback

Repeatedly test and verify that safety requirements are met in the final product. Incorporate lessons learned from quality issues or defects into future improvements.

Today’s automobiles, often referred to as “computers on wheels,” are highly complex systems of electronics and software. Malfunctions in key semiconductors can jeopardize the lives of drivers and passengers, making ISO 26262 compliance a necessity for semiconductor developers.

ISO 26262 compliance and certification is a vital investment that elevates a company’s future value. In a market with increasing safety demands, continuously strengthening development processes based on ISO 26262 is essential for delivering safer and more reliable semiconductor solutions.

Hermes Solution is your optimal partner for successful ISO 26262 compliance and certification. With extensive expertise, we support you through the entire process, from designing systematic processes to implementation and validation. Together, let’s build a safer and higher-quality future. Contact Hermes Solution today to begin your journey toward excellence.