Hello! Today, I’d like to introduce ISO 26262 Part 5, a key standard for functional safety in the automotive industry. We’ll focus on its role in evaluating safety criteria within hardware components, especially the importance of FMEDA analysis, SPFM, and LFM metrics. Through this post, I hope you gain an understanding of the basic structure of ISO 26262 and its safety evaluation methods.

What is ISO 26262 Part 5?

ISO 26262 Part 5 is an essential international standard in the field of automotive functional safety. It provides various assessment methods and criteria to analyze faults within hardware components and ensure system safety. This standard outlines how to classify faults via Failure Mode Effects and Diagnostics Analysis (FMEDA) and evaluates hardware system safety by calculating the Single Point Fault Metric (SPFM) and Latent Fault Metric (LFM).

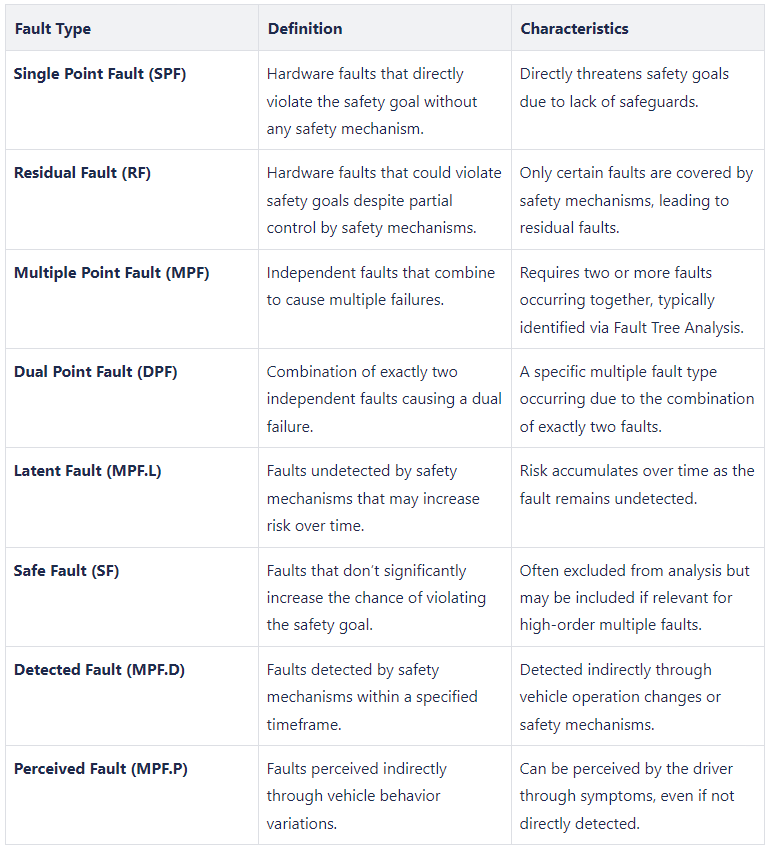

Types of Faults Defined in ISO 26262-5

ISO 26262 classifies fault types in a detailed way, considering each fault’s impact on system safety. Below is a table summarizing each fault type.

Fault Classification within Hardware Elements

ISO 26262-5 only analyzes safety-relevant faults within hardware. The fault classification process is provided as a diagram, excluding faults that do not have a high likelihood of violating safety goals from the calculation of safety metrics. This systematic approach ensures a focused analysis on necessary faults.

Structural Metrics: SPFM and LFM

Two important structural metrics in ISO 26262-5 are SPFM (Single Point Fault Metric) and LFM (Latent Fault Metric), both essential for quantitatively evaluating hardware safety.

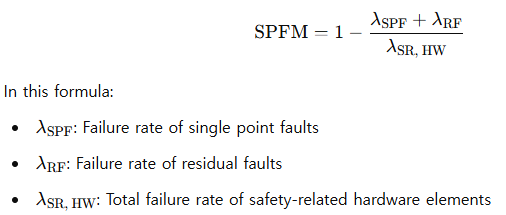

- Single Point Fault Metric (SPFM)

Definition: SPFM measures the extent to which single and residual faults are minimized, assessing the capability to manage faults through design and safety mechanisms.

Calculation Method: SPFM is calculated using a specific formula defined by ISO 26262.

Significance: A high SPFM value indicates that effective safety mechanisms are in place. This is particularly crucial for components with ASIL levels B, C, and D, contributing to the prevention of safety goal violations.

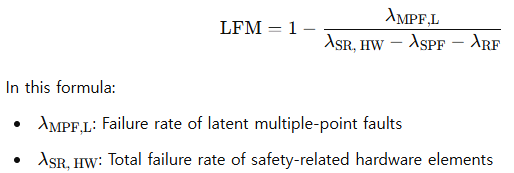

2. Latent Fault Metric (LFM)

Definition: LFM evaluates the ability to manage faults that can accumulate over time without detection.

Calculation Method: LFM is calculated using the formula specified in ISO 26262.

Significance: A high LFM value indicates an effective detection and management of latent faults, reducing risks over time. It is especially important for ASIL levels B, C, and D.

Fault Analysis and Metric Calculation through FMEDA

FMEDA (Failure Mode Effects and Diagnostics Analysis) is essential in ISO 26262-5 for fault classification and the calculation of SPFM and LFM metrics. FMEDA diagnoses hardware element failure modes and their potential to violate safety goals, evaluating the scope of safety mechanisms and diagnostic coverage.

Through FMEDA, the following can be analyzed:

Failure Rates for Single Faults (SPF) and Residual Faults (RF): Faults are classified based on the application of safety mechanisms, deriving failure rates required for SPFM calculation.

Failure Rates for Multiple Faults (MPF) and Latent Faults (MPF.L): The failure rates of multiple and latent faults are calculated to assess diagnostic coverage required for LFM calculation.

FMEDA forms the foundation for systematically calculating metrics according to ISO 26262-5, enabling precise identification and classification of fault types and safety goals.

Importance and Target Values of SPFM and LFM

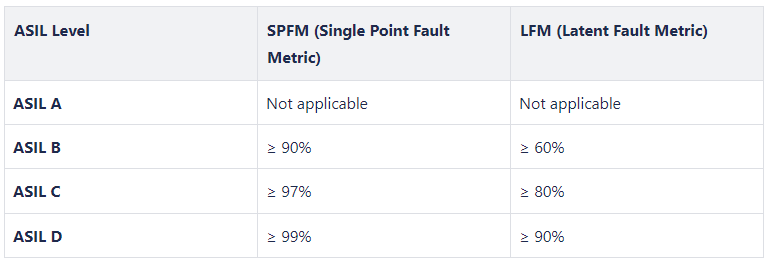

SPFM and LFM are crucial metrics for meeting ASIL requirements defined by ISO 26262. They quantitatively evaluate the effectiveness of system design and safety mechanisms, contributing to hardware safety optimization aligned with fault types and safety goals.

The target values for SPFM and LFM by ASIL level are as follows:

SPFM Target Value: Aims to reduce failure rates of single and residual faults, requiring higher SPFM values as the ASIL level increases.

LFM Target Value: Assesses the capability to manage and detect latent faults, with higher ASIL levels requiring higher LFM values.

These metrics are essential to meet ISO 26262’s stringent safety standards and enhance the reliability of automotive hardware.

Conclusion

The fault classification framework of ISO 26262 Part 5 and the SPFM and LFM metrics are vital tools for evaluating and enhancing functional safety in automotive hardware. By identifying and categorizing faults effectively through FMEDA, high safety standards can be met.

ISO 26262 Part 5’s systematic approach is essential for automakers to manage faults within systems effectively and strengthen safety.