Hello, engineers!

We are Hermes Solutions, offering tailored solutions in software development quality (ASPICE), functional safety (ISO 26262), and cybersecurity (ISO/SAE 21434) for automotive systems.

Today, we will discuss Functional Safety (ISO 26262), an essential aspect to consider in the early stages of developing vehicle electrical and electronic systems (software-based). ISO 26262 is a crucial international standard for ensuring the functional safety of automotive electrical and electronic systems. Safety considerations from the initial development stages are critical.

ISO 26262 Part 3: Concept Phase

The initial development stage of ISO 26262 is known as the “Concept Phase,” and it corresponds to Part 3 of the twelve parts of the standard. ISO 26262 Part 3 addresses four main topics:

1. Item Definition

The first step is to clearly define the “Item” being developed and establish its boundaries. An “Item” can be a controller supporting driver functions, such as an Adaptive Cruise Control (ACC) system or Airbag, or a simple controller offering straightforward features like a vehicle window mechanism.

In this stage, you consolidate the functional requirements, relevant regulations, and the performance of the controller in question, clearly defining the item’s boundaries. It’s also vital to define the Functional Safety Concept and set initial Safety Goals.

2. Impact Analysis

The next step is Impact Analysis. This involves determining whether the Item is new, modified, or an existing product used in a new environment. For example, if an existing airbag system is applied to a new vehicle model, the lifecycle adjustments and necessary safety activities must be identified.

Suppliers (Tier 1 or Tier 2) must conduct this analysis for their areas of responsibility, considering environmental and operational condition changes.

3. Hazard Analysis and Risk Assessment (HARA)

The third step involves Hazard Analysis and Risk Assessment (HARA). This stage identifies potential hazards arising from product malfunctions and evaluates the associated risks. For instance, you might analyze the potential of a Lane Keeping Assist System (LKAS) steering a vehicle into danger, threatening the driver’s safety.

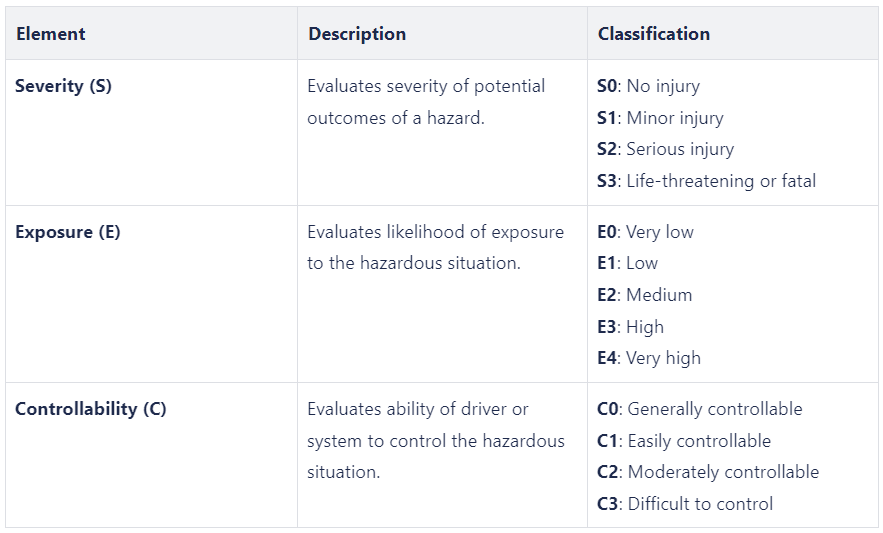

This process involves evaluating the Severity, Exposure, Probability of Occurrence, and Controllability of hazardous events to determine the Automotive Safety Integrity Level (ASIL) and establish Safety Goals based on this analysis. It is also important to analyze not only functional failures but also system-level malfunctions.

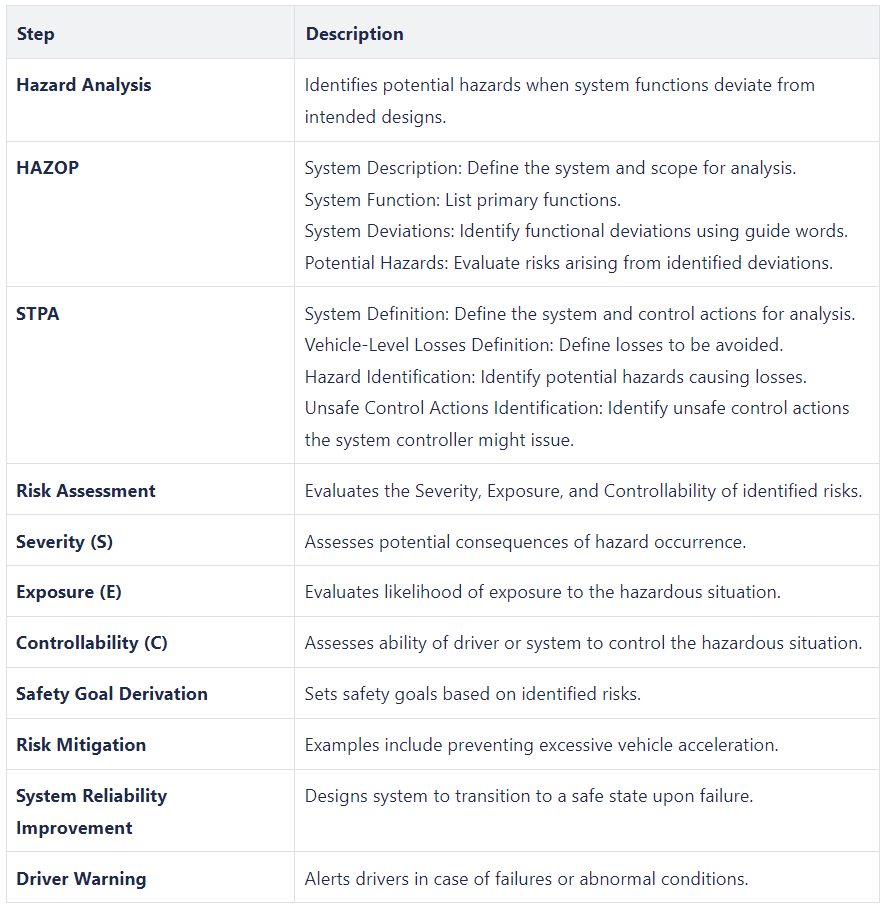

Detailed Steps of HARA

HARA Evaluation Elements

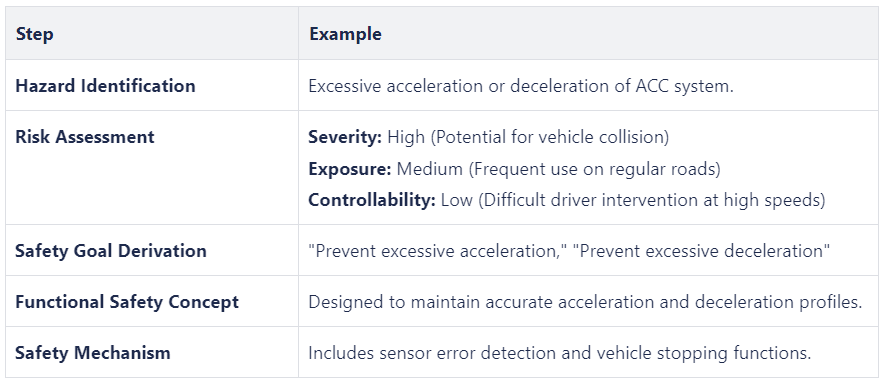

Example Analysis

For more detailed information about HARA, please refer to our previous post on ISO 26262: Hazard Analysis and Risk Assessment.

4. Safety Plan

Finally, one of the critical activities in the early development stages is establishing a Safety Plan. The safety plan provides a structured foundation for executing safety-related activities throughout the project. It defines necessary safety activities for each phase and clarifies responsibilities and timelines.

As illustrated above, considering functional safety from the early development stages is crucial. Understanding and implementing the main topics of ISO 26262 Part 3 significantly enhances the safety of automotive electrical and electronic products.

At Hermes Solutions, we are committed to supporting your successful project execution. Thank you.